Most woodworking projects consist of joints and connecting structures that form a complete piece. The integrity and durability of woodworking pieces with joints are determined by the stability of joined boards or structures. This is why nails, wood screws, glue, and clips are essential components in a woodworking workshop.

In woodworking, the strength level a joint needs to meet in order to function properly usually determines the attachment material or item used. When building picture frames or smaller wooden items not expected to carry weight, glue serves as an excellent attachment material but for larger pieces expected to support wright more is needed. In this case, a nail or a wood screw is the recommended option for supporting joints in larger pieces.

Although nails can provide the attachment strength needed to build durable pieces, professional woodworkers, as well as, experienced hobbyists shun it. This is because of the processes used in nailing wooden pieces. If a hammer is used, the force has the ability to scour the surface of wooden boards and a nail gun also distorts surfaces. Nail is also shunned because of the difficulties with removing it from wooden pieces. The shortcomings of working with nails are why the wood screw is the most popular attachment component used in woodworking.

Why Use Screws for Woodworking Projects

The popularity of wood screws is down to two major reasons; its ease of use and the diverse options available to woodworkers. In terms of ease of use, anyone who has attempted to remove nails from wooden boards, get the applied glue to loosen its grip, and unscrewed a screw will agree that unscrewing is the easier process of the three.

Applying wood screw to wooden pieces also involves using either a manual screwdriver to turn the screw in or a power tool. These two options are safe and straightforward processes and it gets easier if threaded channels have already been created for the screw.

Another important reason why screws are used is because of its support for wood expansion. When building furniture for outdoor use or furniture that will be exposed to heat sources, the joint attachment used must be able to manage the expansion process while maintaining the structural integrity of the wooden piece. With time, glue can be affected by sunlight and lose its strength while expansions can leave gaps between both pieces if a nail is used. Wooden screws provide support for wooden structures as they expand or contract which makes them the better choice for woodworking.

Glue can also be used alongside wooden screws. This adds an extra layer of protection to the structure and ensures the attached pieces remain stuck together for the long term. Although glue provides a cleaner finish than screws, combining both options where surface finish is not the most important priority is the recommended option to take.

The Anatomy of a Wood Screw

Wood screws consist of four components. These components include;

- The pointed tip – The tip is the sharp end of a screw and it serves as a guide that opens the way for the other parts of the screw to pass through. There are different types of screws and many come with differently designed tips but all serve the purpose of guiding the screw through a piece of wood.

- The shank and thread – the shank is the straight piece that runs from the head to the tip of a screw. The shank serves as the support for the threads twisting through the shank. These parts form the body of the screw and they move into the wood when a screw is applied or screwed in.

- The head – The head is the extended surface at the top end of the screw. The head comes in different shapes and sizes. It serves as the surfaces where the driving force is applied to move the screw through a piece of wood. There are different types of head shapes and they include the flathead screw, slotted screw, Philips screw among others.

What kind of Wood Screws Should You Use?

Now to the meat of the matter, what type or kind of wood screw is best for your woodworking projects? The answer to this question is it depends on the project and what you intend to accomplish. There are diverse types of screws out there and why some serve the same purpose others are for specialized use. Here, the different types of screws will be outlined, as well as, the use cases for them.

Standard wood screws

When screws are mentioned, the picture that immediately comes to your mind is that of a standard wood screw. The standard wood screw is designed to have a tapered head and a semi-threaded shank that tapers off at the pointed tip of the screw. Standard wood screws are generally used everywhere including cabinets, furniture making, and decorative pieces. You can’t go wrong by having a couple of standard wood screws in your toolbox.

Drywall screws

Drywall screws are also popular options that can be found across workshops globally. The drywall screw is cheap and thinner than the standard wood screw in terms of bulk or diameter size. The drywall screw is used in cabinets and furniture making. Its only downside is its thin shank which may cause the screw to break during application.

Multi-purpose production screw

The multi-purpose screw is similar to the standard wood screw with a difference. The difference is in the length of the shank and thread which are shorter than the standard wood screw. The screws are excellent for woodworking but are expensive wood screws compared to other options.

Deck screws

Deck screws are built for outdoor use and are made of hardened steel. The screw has elongated shank and thread and they are also resistant to corrosion.

Stainless Steel Screw

If defeating corrosion is the target, stainless steel screws provide excellent resistance to corrosion. These screws can come in different configurations or design as long as it was made from steel. Like deck screws, stainless steel screws are expensive due to the corrosion resistance services they offer.

Pocket Screws

self-drilling screws are a lifesaver when applied on wood because the ease the application process by reducing the strength to be applied. Pocket screws are self-drilling and are designed with a wide head that grabs the shoulder created from drilling pocket holes.

Machine Screws

As stated earlier, not all screws come with a pointed tip and the machine screw is an example of this. Machine screws are designed to have fully threaded shanks and no point at the tip. They are secured in place by nuts in a similar fashion to the traditional bolt and nut configuration you are familiar with. These screws are generally used to fasten boards together.

Sheet Metal Screw

Variations of the popular wood screw exist and the sheet metal screw is one. The sheet metal screw is a wood screw with a pan head. The screw is widely used by woodworkers for fastening joints and attaching boards for carpentry or cabinetry.

Top 10 Best Wood Screw Sets to Have

Having screw sets in your workshop is an important recommendation for every woodworker or aspiring woodworker. Wood screws will always feature in your craft which is why stocking up on them ensures you do not have to make regular store runs or orders for screws. Here are ten screw sets you should consider purchasing for your toolsets:

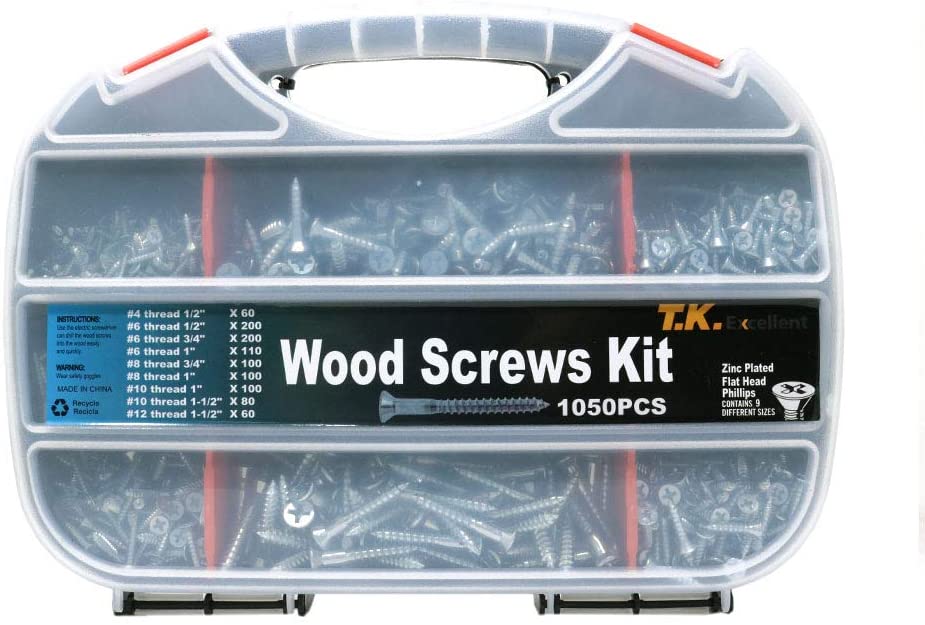

TK Excellent Phillips Flat Head Kit

Wood screw sets come with screws of different lengths or designs depending on the kit you purchase. This ensures you have what you need for different applications. The Philips flat head kit contains 150 flat head wood screws of different lengths. The screws are packed in clear plastic sections and provide you with 6 sizes of flat head wood screws to work with.

The longer 6 inches screws follow the multi-purpose screw design with a threaded shaft starting almost halfway from the head. The shorter screws have threaded shanks running through their length.

Rustark Drywall Screws Kit

The Rustark kit contains 160 pieces of drywall screws with varying lengths. The kit is made from plastic and consists of different sections for each of the different sizes it provides.

The screw is designed to have a coarse thread and a sharp tip that deliver excellent grip when used on wooden structures. The Rustark drywall kit consists of screws suitable for a wide range of applications including the installation of drywall, fastening wooden sticks, and other support structures. The screws are made from black cardboard steel which adds to the durability of the product.

FIRMEST 304 Stainless Steel Wood Screws

The FIRMEST 304 screw set consists of a mixture of standard wood screws, deck screws, and flat head screws. The screws are made from stainless steel and are resistant to corrosion. They are excellent fastening screws every woodworker should have due to the diverse options available to them. The kit consists of 255 pieces and it’s ideal for both indoor and outdoor use.

Phillips Pan Table Metal Screw Kit

This pan head self-tapping screw set is another excellent fastening toolset Phillips offers to woodworkers for joinery and finishing applications. The screws within this kit are made from stainless steel and are resistant to corrosion which also makes them excellent options for outdoor applications.

The screw set consists of deck screws with the traditional Phillips star or cross screw head and a rounded flat head. There are 280 pieces in this kit and a valuable marine fridge magnet is included in the package.

DYWISHKEY 360 Stainless Steel Hexagon Socket Head Screws

The DY WISHKEY screws are sheet metal screws which also have their diverse applications in woodworking. The screws in this set come with hexagon socket heads which simplifies the process of application. They are also made from stainless steel which means they’re resistant to corrosion and are excellent options for outdoor applications.

GBW Squeeek No More 3233 Kit

This screw kit consists of wood screws specially designed for application on floorboards. The screws in the kit are the average woodscrews but with square-drill holes on the flathead.

The threads run through the shanks from its pointed tip to close to its head. The screws come in one size and are built for application on carpeted boards, hardwood, and vinyl floors. As a woodworker, you can also choose to use these wood screws for personal applications because the flathead is aesthetically pleasing to look at.

The Hillman Group 42073 Walldog Kit

The Hillman kit consists of sturdy screws that can handle diverse applications. Although the Hillman group calls it a contractor screw, these screws are deck screws with widely spaced threads.

The screw is made from stainless steel which makes it resistant to corrosion and good to use on wooden structures built for outdoor use. You can make use of these sturdy screws without having to drill through your wooden structures before application.

Kreg SK04 Screw Starter Set

The Kreg SK04 kit consists of pocket screws with diverse head designs. The screws include heads with Phillips flat head design, hexagonal heads, and self-drilling heads. The threaded shafts begin from half the length of the screw-down to its pointed tip thus making it a multi-purpose screw.

Kreg SK04 screws are great for Kreg joinery tasks and fit into pocket holes to make strong lasting joints. According to Kreg, the coarse-threaded screws are built for softwoods while the fine-threaded screws are designed for hardwoods. The screws are made from stainless steel which means they are resistant to corrosion and are durable for woodworking.

DVKNM High-Quality Black Steel Screws

This 160 screw set is designed with screws that have fully threaded shanks and a pointed tip. The screws are made from black steel which adds to their durability and ensures they are resistant to corrosion and rust. The DVKNM screw is designed for furniture making and installing drywall.

The aggressive screw twist design it incorporates makes driving it into a piece of wood a quick and efficient process. DVKNM made use of a durable plastic package with different sections to store its high-quality black steel screws. This ensures you are protected from the sharp edges of its screws and misplacing individual screws.

Mexi Carbon Steel Wafer Head Screw Set

The Mexi wafer head screw set consists of 360 pieces of self-tapping wood screws with crossheads for woodworking applications. The screws are made from carbon which ensures they are durable and can be used on hardwood. The carbon steel build also means it is resistant to corrosion. The screws are deck screws and their threaded shanks extend from the head to the pointed tip of the screw.

Conclusion

Wooden screws are affordable fastening tools and the options listed here are within the $10 to $30 range. Experienced woodworkers understand the importance of keeping spare screw kits handy at all times and this is one woodworking hack every beginner should put into practice.