The versatility of the 3D printer makes it one of the commonly used tools in across every industry. 3D printing or additive manufacturing provides a complementary solution for producing parts you may not want to spend too much time crafting or do not have the ability to design. This makes it a beneficial tool that can benefit woodworkers, crafters, cabinet makers, and anyone who makes decorative pieces using wood.

Any woodworker interested in digital technologies or how industry 4.0 concepts can aid the craft of woodworking will find the 3D printer an important ally for getting work done. To take advantage of the creativity and versatility 3D printing offers, knowledge of 3D printing and the additive manufacturing process is important for woodworkers. Thus, this comprehensive guide will introduce the use of 3D printing in woodworking and how you can benefit from its application.

What is 3D Printing?

3D printing involves the use of a 3D printer to build three-dimensional objects from a computer-aided design (CAD) model. The 3D printer prints out the object by successively adding layers to a platform until the 3-dimensional object is fully formed. This is why the process of 3D printing is also known as additive manufacturing.

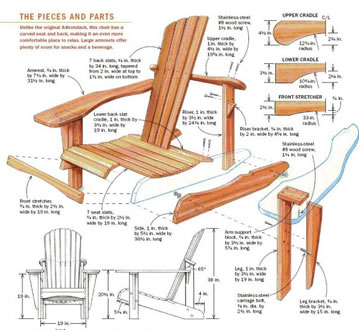

This brief definition shows that three important items are needed for additive manufacturing. These items include; the 3D printer, the 3D printing material, and the 3D CAD model. The 3D printer serves as the machine which provides the build platform, nozzle, and space for 3D printing. Printing materials are the physical materials the machine or device uses to build the 3D object while CAD models provide the direction for producing the object. This means you will need a 3D CAD model for your woodworking designs to get started.

Although 3D CAD models serve as blueprints for 3D printers, they must first be broken down into the language or format the 3D printer understands. To do this, slicing software applications are used to slice 3D CAD models and create STL files which are then transferred to a 3D printer to print.

Types of 3D Printing Technologies

There are different 3D printing technologies currently in use within the available 3D printers you can buy. These different technologies defer according to the printing technique they apply and in some cases, the material they use for 3D printing. The popular 3D printing technologies available to you include:

- Material Extrusion; Fused Deposition Modeling (FDM) – The FDM printing technology involves heating thermoplastic materials to its melting point and extruding the material onto a build platform layer by layer. FDM makes use of thermoplastics such as PLA and ABS filaments. Other specialized materials you can use include wood infused thermoplastics which actually produce objects that feel like wood.

- Vat Photopolymerization – Photopolymerization involves the use of a heat source to cure liquid photopolymers in successive layers to form the 3D object. For this technique, the materials used are liquid photopolymers which are also called resins. The popular vat Photopolymerization technologies currently in use are Stereolithography (SLA) and Digital Light Processing (DLP).

- Powder Bed Fusion – This 3D printing technology involves the use of a heat source to fuse powdered particles layer by layer to form the 3D object. In this case, the heat source can be electron beams and the materials are powdered metals. The commonly used power bed fusion technique is selective laser sintering (SLS).

- Other 3D printing technologies exist such as material jetting, binder jetting, sheet lamination and direct energy deposition. It is highly unlikely you will use or need these commercial 3D printing technologies to aid your woodworking activities.

For woodworkers, the versatility in terms of material use FDM 3D printers offer makes it the best choice for supporting woodworking efforts. You can find quality-grade FDM 3D printers within the $150 to $500 range and purchasing filament is cheaper than resins and other forms of 3D printing materials.

What’s it like to use a 3D Printer?

The process of using a 3D printer has been described in the previous section but this section will provide step by step highlights of how the 3D printing process is executed. Starting with the purchase of your 3D printer, a 3D printer may come either assembled or not and assembling the average 3D printer takes approximately 30 minutes.

- The first step starts with getting a 3D CAD model that will serve as your woodworking design and the blueprint for printing. There are three different ways to get 3D CAD models and they involve using a woodworking design software application to create 3D models, downloading models from free platforms or hiring an experienced freelancer to create models for you.

- To convert the 3D CAD model to STL a slicing software application will be required. Slicers are easy to use and all you have to do is upload the 3D model into the slicer application and it slices the model into printable parts. Load the machine with the filament of choices such as PLA or ABS.

- The sliced file can then be fed to the 3D printer using a USB stick, Bluetooth or Wi-Fi connection. Apply the printer’s automated settings for your designs and the material you intend to use and start printing.

- The printing process may take a few hours and you should inspect its progress in intervals.

With these four steps, you can get started printing your woodworking ideas. The plug and play approach to 3D printing makes it an easy process for beginners and woodworkers interested in exploring its use.

The Benefits of 3D Printing to Woodworking

Additive manufacturing can benefit the woodworking community in diverse ways. Here, the five important advantages it provides will be highlighted.

- Enhances miniature wood-crafting – Wood crafting involves the creation of decorative pieces and carvings that can be sold commercially or used as domestic decorations. A 3D printer produces complex miniature wood-crafting faster than handcrafting complex pieces.

- Enhanced Accuracy – A 3D printer digitally recreates the designed CAD model to a high level of accuracy in terms of dimensions. With 3D printing, what you design is what you get. This level of accuracy makes it an advantageous process for building items that require their dimensions to be accurate.

- Speeds up Production – The woodworker spends hours on his craft and the more complex it is the more time is spent ensuring it comes out great. 3D printing takes time to complete but this time is less than the duration for handcrafting complex designs.

- Complements woodworking efforts – The ability of an FDM 3D printer to use diverse materials creates an avenue for the printing of accessories for woodworking projects. Accessories include ceramic or plastic handles and knobs or other items that complete woodworking projects.

3D Printing Projects for Woodworkers

To get you started with 3D printing parts and tools that can enhance your woodworking craft, browsing through a collection of 3D printing projects can help. This section provides some easy 3D printing projects you can start with as you add another craft to your woodworking abilities.

Clamping Brackets

This project focuses on 3D printing clamping brackets which can be used to clamp mitered joints on picture frames, and wooden boxes. For this project, an FDM 3D printer and colored PLA filament would be used. The clamp is a simple structure with an elongated base with a hollowed semi-circle clamp at one end. You can download the STL file for the clamp bracket here to kick-start the process.

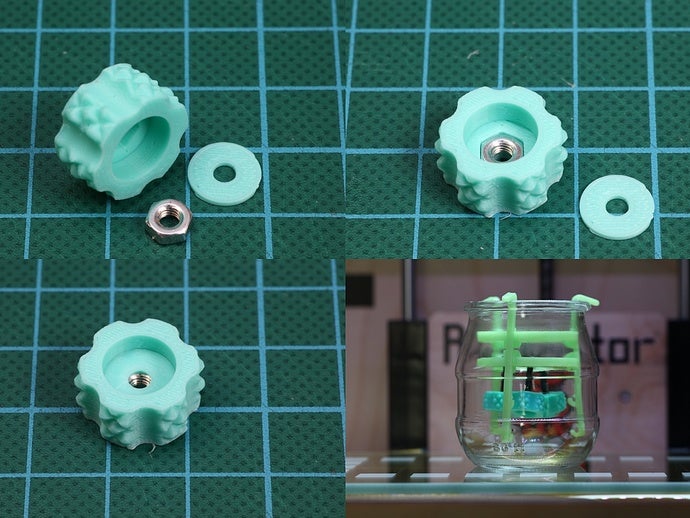

Knobs

3D printing is an excellent option for manufacturing threaded knobs with complex or more artistic designs. If you plan to make use of knobs to enhance the aesthetics of your project then the versatility of a 3D printer is your best option for such a task. You can find the STL files for a threaded knob here. This knob is a simplistic four-leaf clover design.

Rounded Corner Templates

Rounded corners are used as measuring or dimensioning tools to make rounded cuts at the edge of boards. The 3D printer is great for making simplistic tools such as these and other template ideas for woodcarvers. You can download the STL files for the rounded corners here. These corners come with different dimensions for diverse uses.

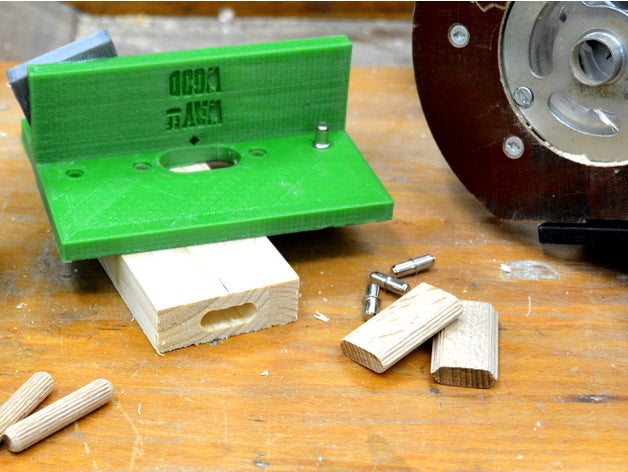

Mortise Layout Templates

Another helpful template you may choose to 3D print is the mortise layout. These templates are useful tools for laying out mortise on your stock to guide other activities. These activities could include routing or chiseling across the stock. The mortis layout template can come in different shapes and sizes but this option is a hollowed square where the hollow serves as the marking space. You can download the mortise layout STL file here.

Corner Brackets

Temporary corner brackets provide an easy method for joining or supporting butt joints and T joints during the joining process. A corner bracket is a support tool for woodworkers who do not have assistants to help with the building process. The corner bracket looks like a butt joint with a support structure across the angle both of its ends form. You can download the corner bracket STL file here and get started with 3D printing extra supporting tools for your workshop.

Angle Gauge

An angle gauge is a popular tool used in manual 2D drafting processes. The tool is used to draw angles and can also be applied to wooden structures or boards. The angle gauge is capable of producing three different angles including 30, 60, and 90 degrees. You can choose to design your angle gauge by downloading the STL file here.

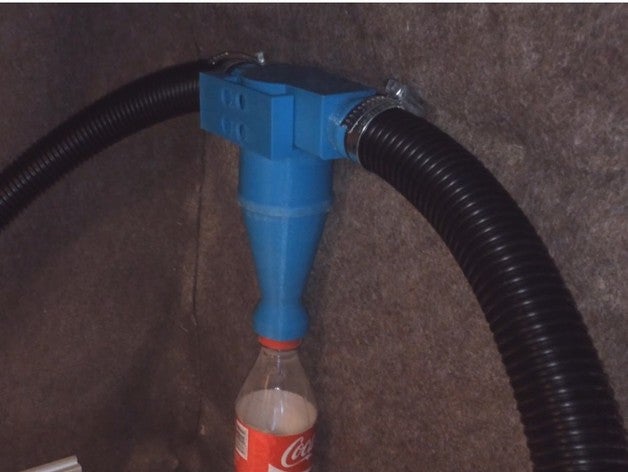

Dust Collector Adaptors

A woodworking shop is notorious for the amount of dirt it produces. This is due to the use of different cutting tools, hollowing tools, and wood to create art. Thus, the dust produced by woodworking processes must be continuously cleared to ensure the woodworker has enough space to work. Dust collector adaptors enhance the dust collecting abilities of vacuum cleaners. You can download the STL file for this dust collector adaptor here. If the adaptor is larger than your required specifications, you can make use of tape to secure the adaptor in place.

These seven items are examples of 3D printed objects that enhance your craft. They are small components that you can 3D print with ease. Woodworkers can also take advantage of larger 3D printers to 3D print wooden sculptures and other support tools.

How difficult is 3D Printing?

Fused deposition modeling is a straightforward process. Many first time users find 3D printing an easy task after using a 3D printer continuously for a month or two. This is due to the plug and plays nature of the 3D printer. Woodworkers will also find this to be true as most of us have learned the importance of patience when creating art.

With 3D printing, having some practical experience is important which is why you are expected to practice until you become good enough to create your own unique designs with a 3D printer. The automated printing features many next-gen 3D printers provide also reduce the challenges you are likely to encounter with using a 3D printer. In many cases, a 3D printer can repair defective STL files, automatically set printing parameters such as the build platform position, and alert you about printing challenges.

It is also worth noting that finished 3D objects may require some post-processing activities to get the aesthetics you desire. The nature of thermoplastic filaments allows you to cut these items, apply sandpaper, and paint as post-processing activities. This means that with a little effort you can start 3D printing unique items and finishing them off in a month or two.

Conclusion

Many woodworkers have found the 3D printer to be a helpful tool that has advanced their craft. You too can take advantage of the support 3D printing offers by purchasing a simple entry-grade 3D printer such as the offerings from Creality or Dremel. These 3D printers are affordable and the materials and power they consume do not add much to the total overhead cost of developing creative 3D prints for your woodworking projects.